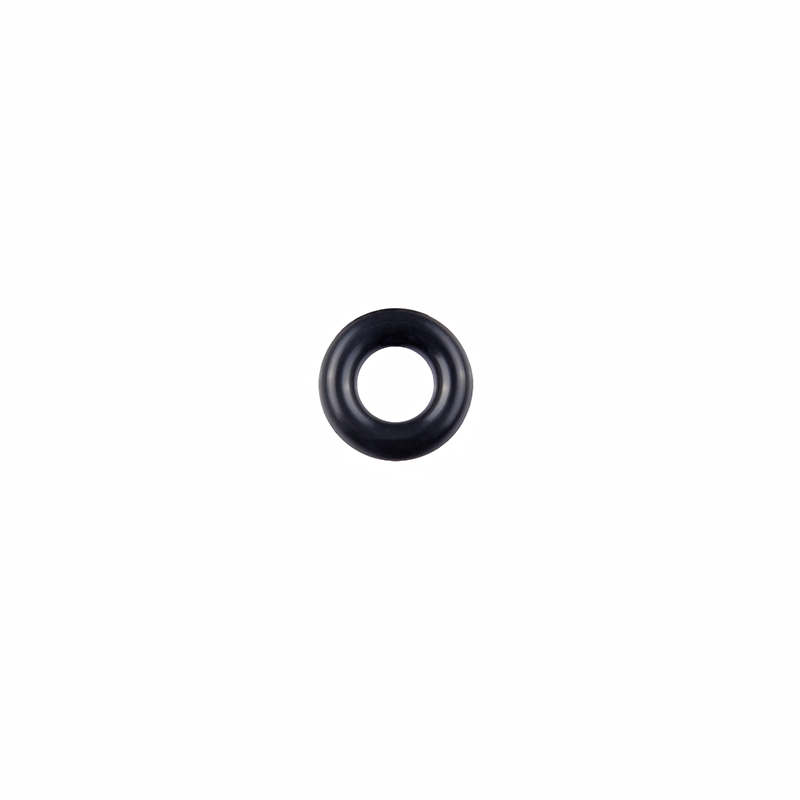

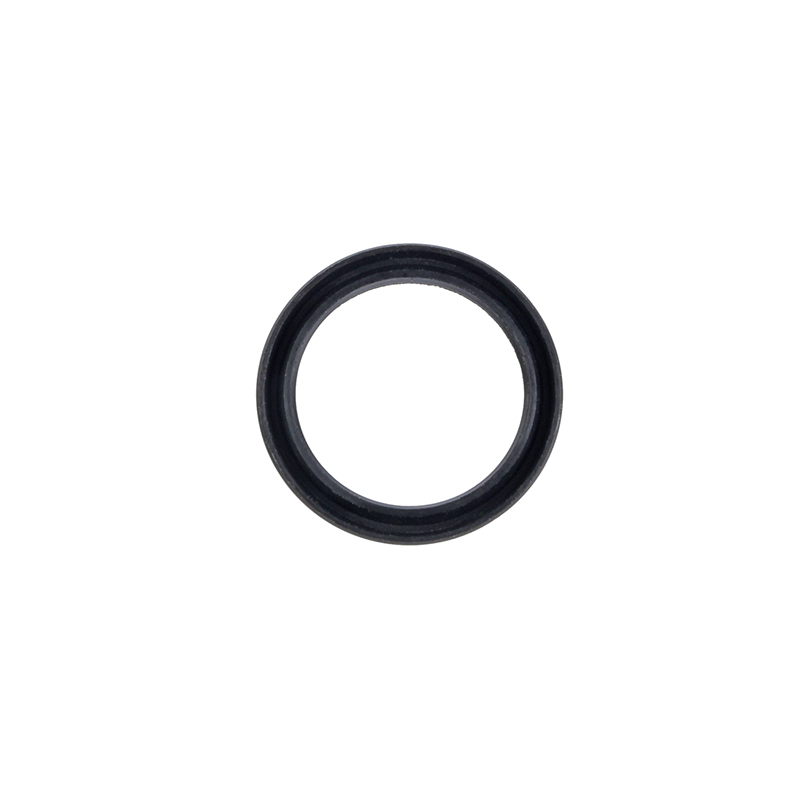

Solenoid Valve Precision O-Ring Solenoid Pump Precision O-Ring

Solenoid Valve Precision O-Ring Solenoid Pump Precision O-Ring

Solenoid valves and pumps are essential components in various industries, including automotive, manufacturing, and medical fields. These devices are responsible for controlling the flow of fluids and gases, ensuring precise and efficient operation in a wide range of applications.

One crucial aspect of solenoid valves and pumps is the precision O-ring. O-rings are small, circular seals made from elastomers such as rubber or silicone. They are designed to create a tight seal between two mating surfaces, preventing leakage and ensuring the proper functioning of the valve or pump.

In solenoid valves, the precision O-ring plays a critical role in controlling the flow of fluids or gases. When the solenoid coil is energized, it creates a magnetic field that attracts a plunger or armature. This movement compresses the precision O-ring against a valve seat, effectively sealing off the flow path. When the solenoid coil is de-energized, the magnetic field disappears, allowing the precision O-ring to return to its original position, allowing the fluid or gas to flow.

Similarly, in solenoid pumps, the precision O-ring is responsible for maintaining a tight seal between the pump chamber and the inlet/outlet ports. As the solenoid coil is energized, the precision O-ring is compressed, blocking the inlet port and creating pressure within the chamber. This pressure forces the fluid or gas to flow out through the outlet port. When the solenoid coil is de-energized, the precision O-ring relaxes, allowing the inlet port to open and refill the pump chamber.

The precision O-ring is crucial in both solenoid valves and pumps as it ensures a reliable and leak-free operation. The material used for the O-ring must be selected carefully, considering the specific application requirements, such as temperature, pressure, and the type of fluid or gas being handled. The O-ring must be able to withstand these conditions without deforming or deteriorating over time.

Regular maintenance and inspection of the precision O-ring are also essential to ensure its proper functioning. Over time, O-rings may wear out or become damaged, leading to leakage or failure of the valve or pump. It is crucial to replace worn or damaged O-rings promptly to maintain the efficiency and reliability of the system.

In conclusion, the precision O-ring is a crucial component in solenoid valves and pumps. It plays a vital role in controlling the flow of fluids and gases, ensuring precise and efficient operation. Proper selection, maintenance, and replacement of the precision O-ring are essential to maintain the integrity and reliability of the system.

Product Features:

Product Category: Solenoid valve precision O-ring

optical double-sided full inspection machine is fully inspected and shipped, with a dimensional accuracy of/-0.01mm, super wear resistance, stable flow, acetic acid resistance, water resistance and corrosion resistance during the life of the product. It can meet ROHS FDA and other requirements as required, and suitable materials can be selected according to the sealing medium.

Our Advantages:

|

Selection of raw materials, safety and environmental protection Advanced equipment, mature technology Precision detection, quality control Value-added services, worry-free after-sales |